Tips and Dimples

Wing Tips

The fiberglass wing tips are over-sized, as usual. I ended up cutting 8” off the end to get maximum clearance through my garage door. A metal strip is added to the inside of the fiberglass to add strength. Still, there’s no significant structure holding the tips on… maybe 3/4” overlap with the wing skins… just enough for a line of rivets all the way around. I can’t help but think that if the tips were much longer, they’d produce enough lift to rip themselves off.

Tiedowns

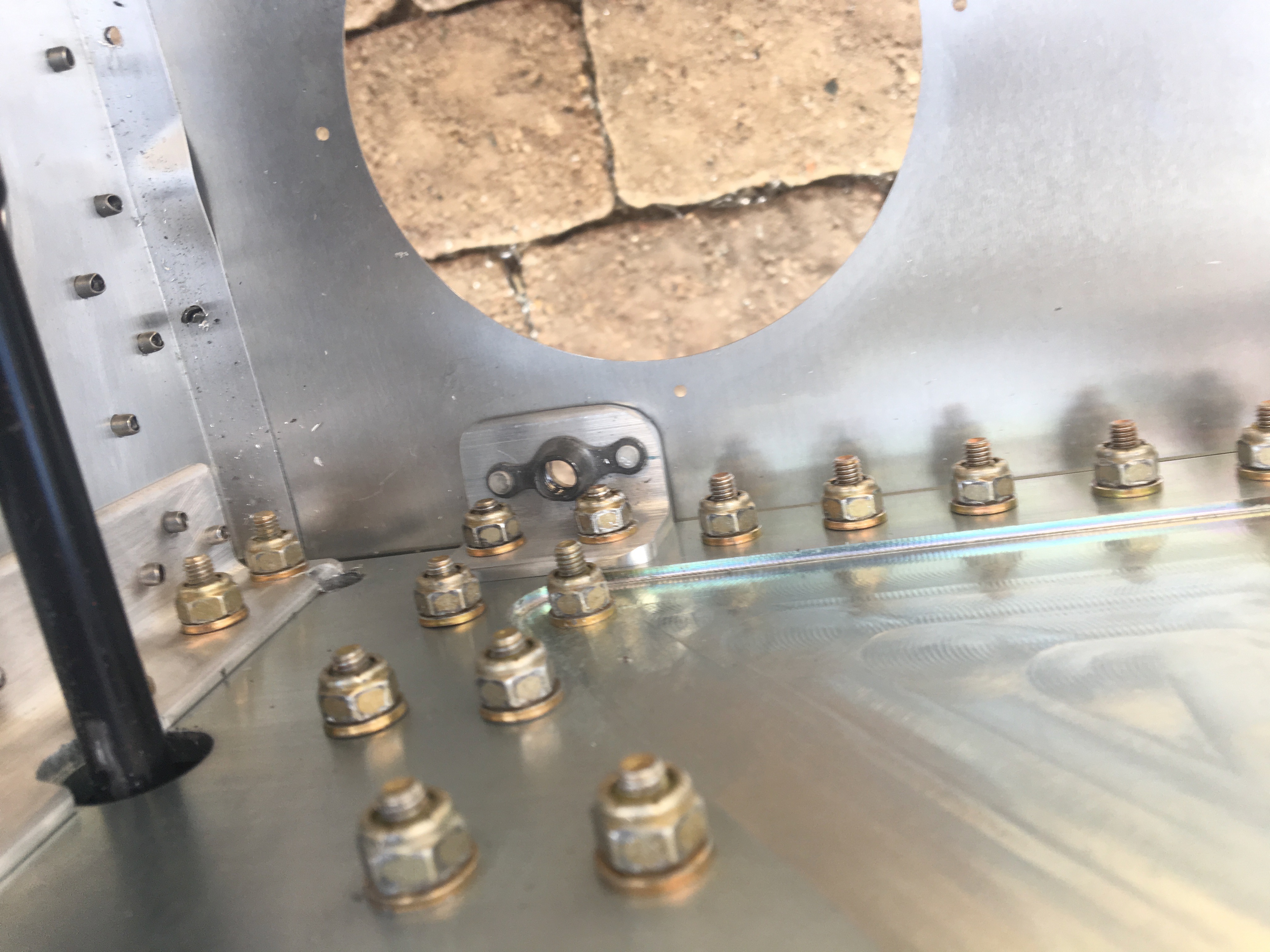

This is a fat nut plate just inside the bottom of the wing skin. It’s from the AirWard tie down kit. When desired, I can screw in an eye-bolt as a tie-down point. You can see it is securely fastened to the spar.

Pitot/AOA

I finally settled on a location for the pitot/AOA tube. Some modification of the Dynon install kit was required, but I feel like I have a much stronger mount then they prescribe. It’s located just behind the main spar. It’d be all the way at the end of the inboard wing but there’s an inspection hole there so it’s about 8” inboard from the end.

TODO: include picture of pitot mount.

OAT

I also placed the Outside Air Temperature sensor on the right wing just behind the pitot tube.

Skin Hole Prep

The rivet prep has begun. Starting with the right inboard skin, I deburred, scrubbed with scotch brite, deburred spars and ribs, dimpled the front skin holes, dimpled the front ribs, and clecoed it back in place. This took almost 4 hours. I started the left side in the afternoon but didn’t finish because my rivet puller broke while using Sonex’s Super Simple Dimple Die.

Only four more skins to go.