Filing/Deburring

Now that I have the plans, and the engine is waiting on parts, I have nothing to stop me from building the rest of the plane…. except my lack of know-how. So I read a book this weekend. Kit Airplane Construction” by Ronald J. Wanttaja. It was great. I learned a ton. I’ve also been watching EAA’s “Hints for Homebuilders Channel”. Also a great resource from which I learned a ton. I’m ready to dive in. I’ll be on the hunt for an experienced homebuilder to review my work and make sure I’m doing it right. If you know anyone, let me know.

Took another tailwheel flying lesson today. Larry said I’ll be ready for endorsement next lesson. I was doing one wheel work all by myself today. Wicked!

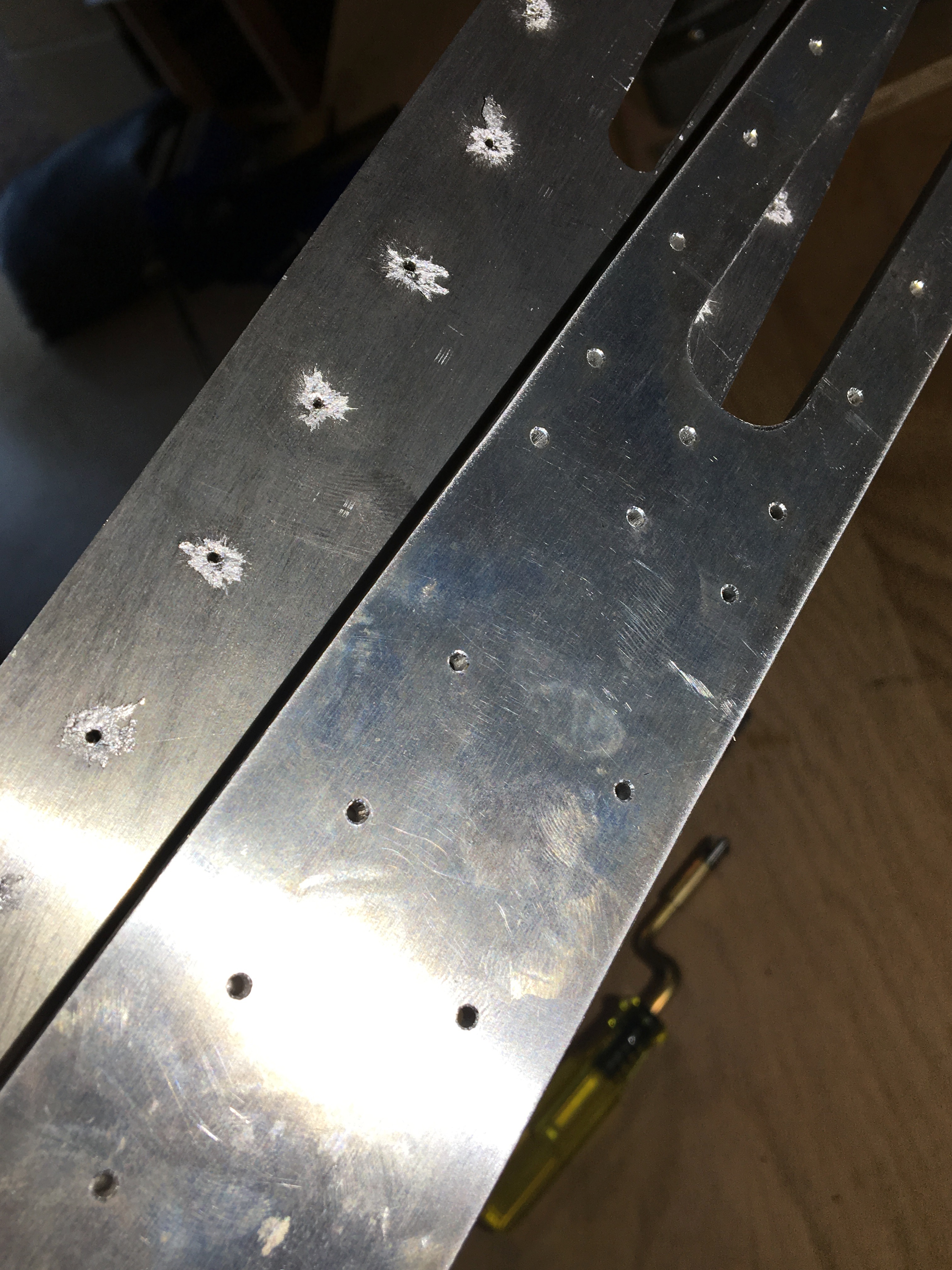

Mark from Sonex recommended I start on the tail, so I am. I flipped the plans to the tail page(s), and hunted for all the parts. Finding parts is a time consuming task by itself. But perhaps the most time consuming task is preparing the parts. Each piece of metal requires love and care before it can be assembled. First, it needs to be filed. The machining process, or sawing, leaves ridges and groves across the edges. These are weak points where stress can build up. It’s critical that the edges be filed down to a smooth, mirror-like finish. In the image below, the left part has yet to be filed while the shiny one on the right has been filed.

Likewise, drilling holes produces similar weak points so every hole must be deburred. There’s a handy little tool that makes it really easy. You can see it in the back ground of the image where I show a deburred part vs one that still has its burrs. Actually, in that example, those splashes are the result of laser cutting but they still need to be deburred.

Had I not done my research, I would have happily assembled these parts without properly preparing each part. Scary! I need to keep researching and I really need to get an expert to advise me.

There are several questions I wrote down. I think I know the answers but I’m gonna call Sonex tomorrow and ask:

- 6061 aluminum used on the OneX is corrosion resistant. Does that mean I don’t need apply corrosion protection for each part?

- Does thinner (0.025”) aluminum require deburring and filing too?

- Some parts are made of different aluminum that has a visual-texture like particle board. Do they require filing and deburring?

- It looks like some parts only have pilot holes drilled. These hole need to be widened? How do I know what drill bit to use?

- At what point do I stop assembling part and replace clecos with rivets?

- What is the process for “pickling” the AeroVee engine?