Workbench & Tools

Last night I was reading through the plans I realized two things:

1) I have a shortage of workbench space. The moment I take the plans (3x2’) out into the garage, I loose at least six square feet of tabletop space.

2) I’m gonna have to bend these metal parts and I don’t know how to do that.

Workbench Space

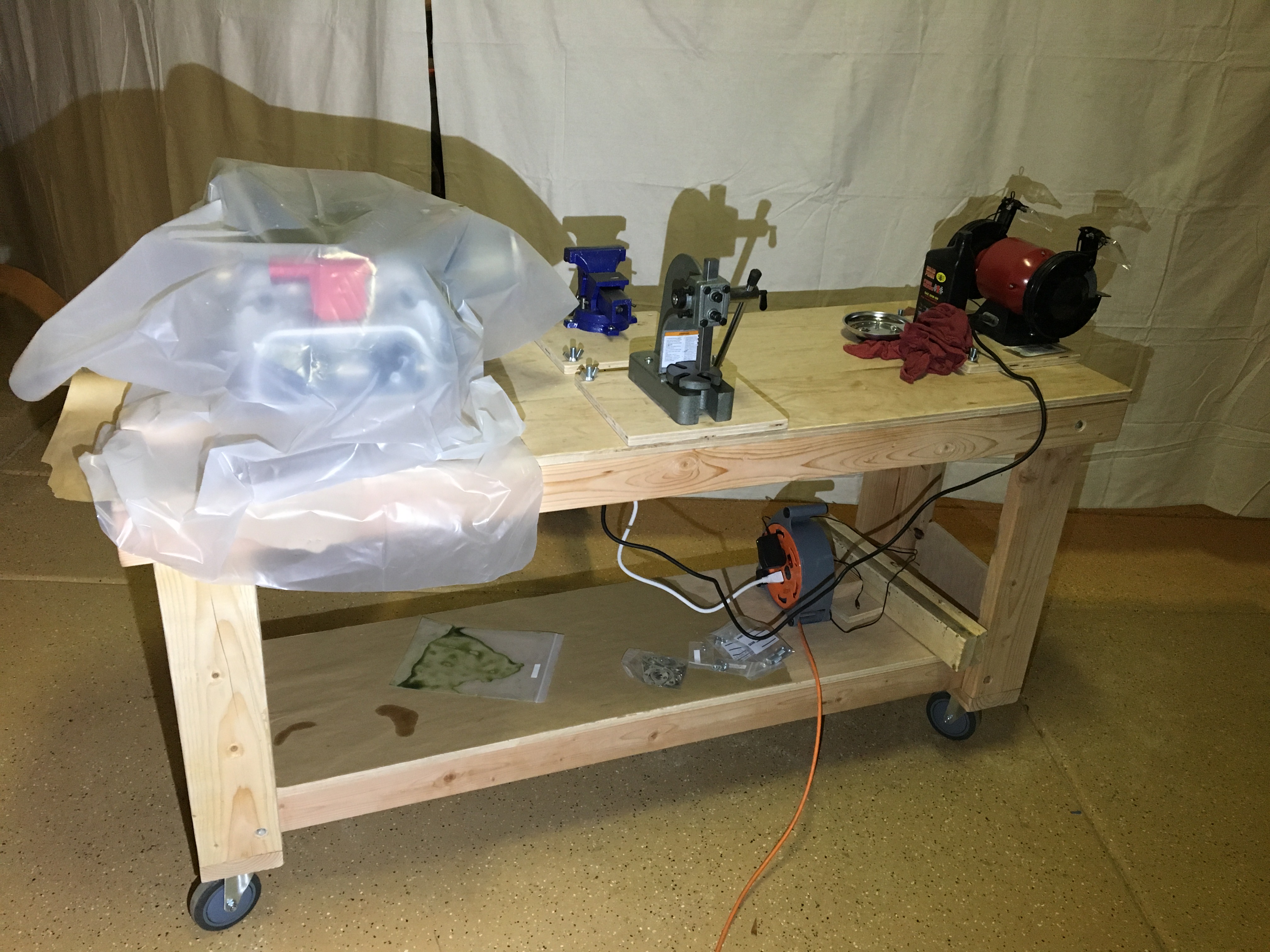

I need the plans in my shop (garage), and I definitely can’t spare the table space. Remember how the kits was delivered on a palette made of particleboard? I still have that, though cut into smaller pieces, because Scottsdale only picks up bulk garbage once a month. Good thing. With that and some 2x4 I kept around, I fashioned a temporary table to hold the plans. It’s nice and tall so I can read it better. See the first picture below.

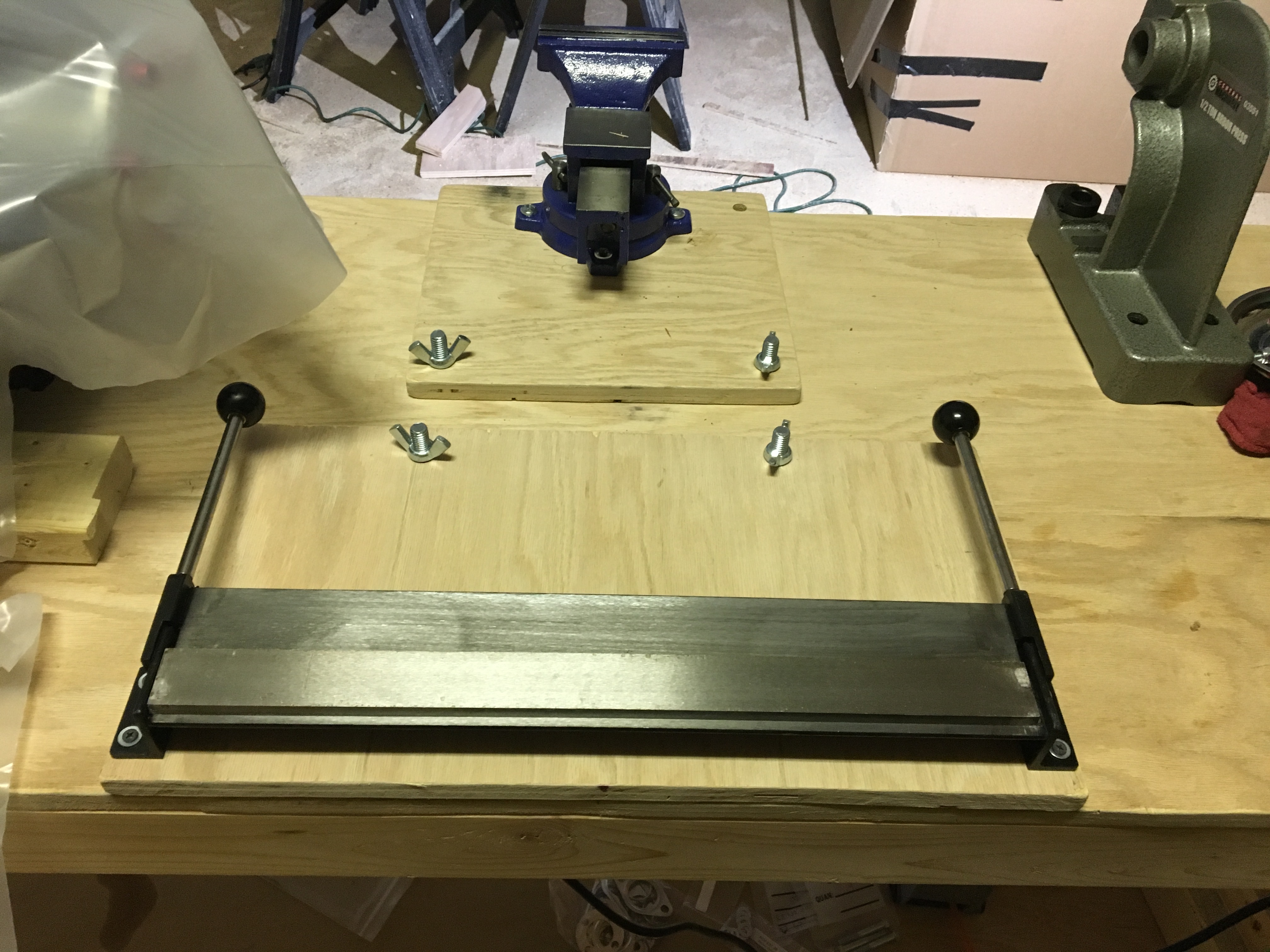

On the topic of workbenches, the second picture shows the workbench I build while waiting for the kit to arrive. Notice the wingnuts, and that all the small board that the tools are on. This is my modular design that I’m rather proud of. You see, the build required lots of tools that need to be mounted to tabletops. Drill press, band saw, griding wheel, vice to name a few. If I mounted all of these directly to my workbench, there’d be no room for more tools to be mounted, let alone space to work. So I bolted each tool to a small board. On each board, I drilled two large holes equally spaced. I sacrificed the pristine surface of my workbench to drill the same pair of holes in four different locations. When a mounted tool is needed, I grab the tool and the board it’s attached to, line up the holes, stick two bolts in and tighten the wingnuts. Easy! And if I want the entire workbench surface, I spin open all the wingnuts and remove the tools. It’s been working well so far.

I fear I’ll need more tabletop space still…

Bending Metal

Sonex has several helpful tool-tip videos. So I looked for some on bending metal parts and was happy to find some. Then mention a “bending break” in one video, and another shows how to use an “arbor press”. I’ve never head of these tools and have no clue where to get them…. except I keep hearing the name “Harbor Freight”. Googled “Harbor Freight”. Oh, it’s a store, online and physical. Oh, they have branches in Pheonix. I swung by today and they sold both the bending break and the arbor press.

The arbor press is hefty metal tool you can see mounted to my workbench below. It basically pushes down REALLY hard. This small model is rated for 1/2 ton. I was amazed when I saw the price tag of $20! I wasn’t planning to get one until that point.

The bending break bends sheet metal. You’ll find breaks that cost into the thousands. The one you see in the picture was $40 and should suit my needs.