Framing the Box

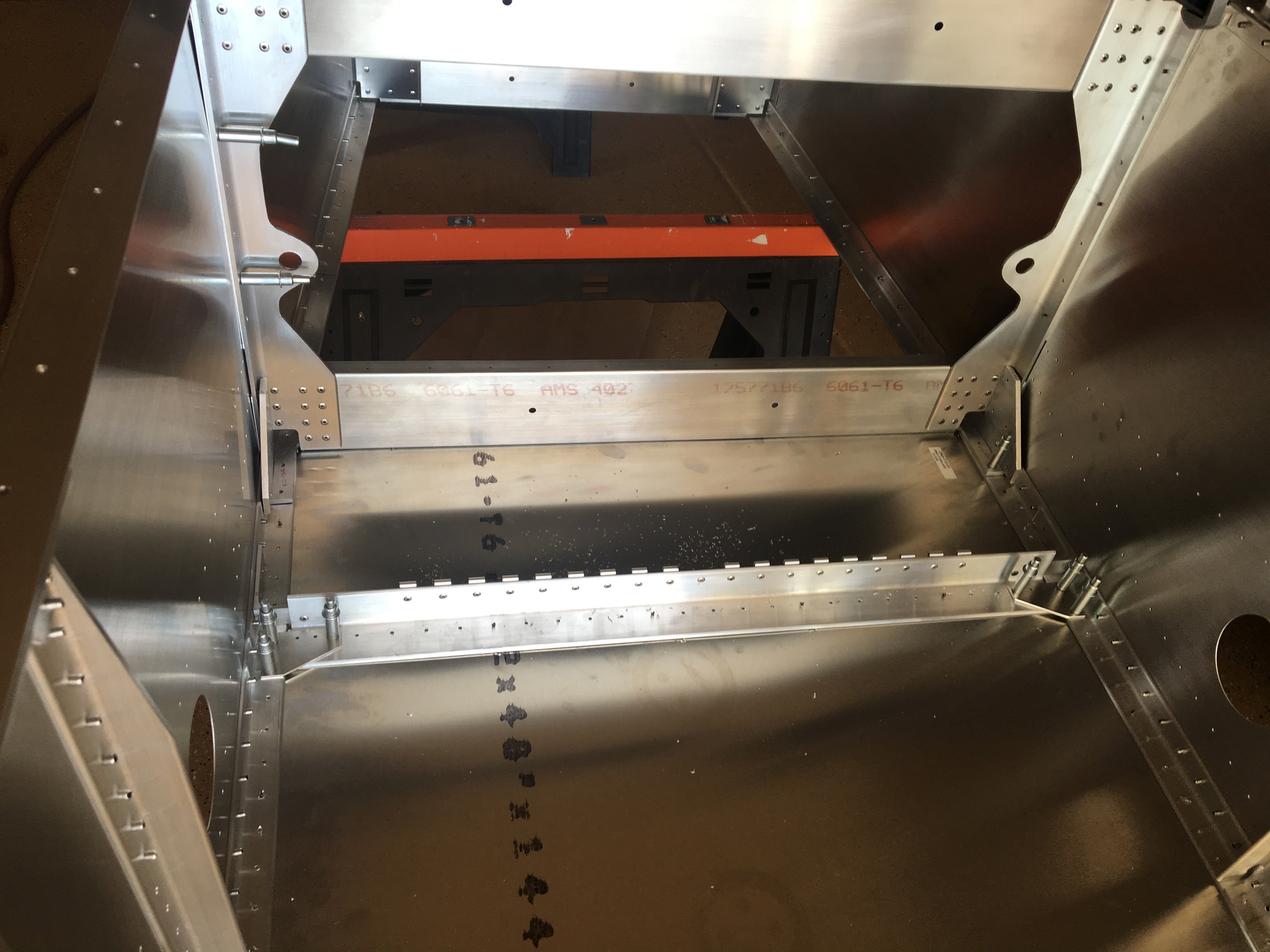

The box floor is drilled and clecoed to the walls. All three of those parts are clecoed to the tail. Now there are a dozen or so beams and angles to add strength and rigidity to the structure. That means more sawing, grinding, and polishing.

In the second picture you can see the seat attach beam that goes across the floor skin, with some piano hinge on the back and two little arms that get riveted to the side longerons. This one took a couple hours to make but it fits in it’s spot perfectly. I was able to grab my creeper from my hangar at Scottdale the other day which was a good thing; it allowed me to slide underneath and drill from the bottom.

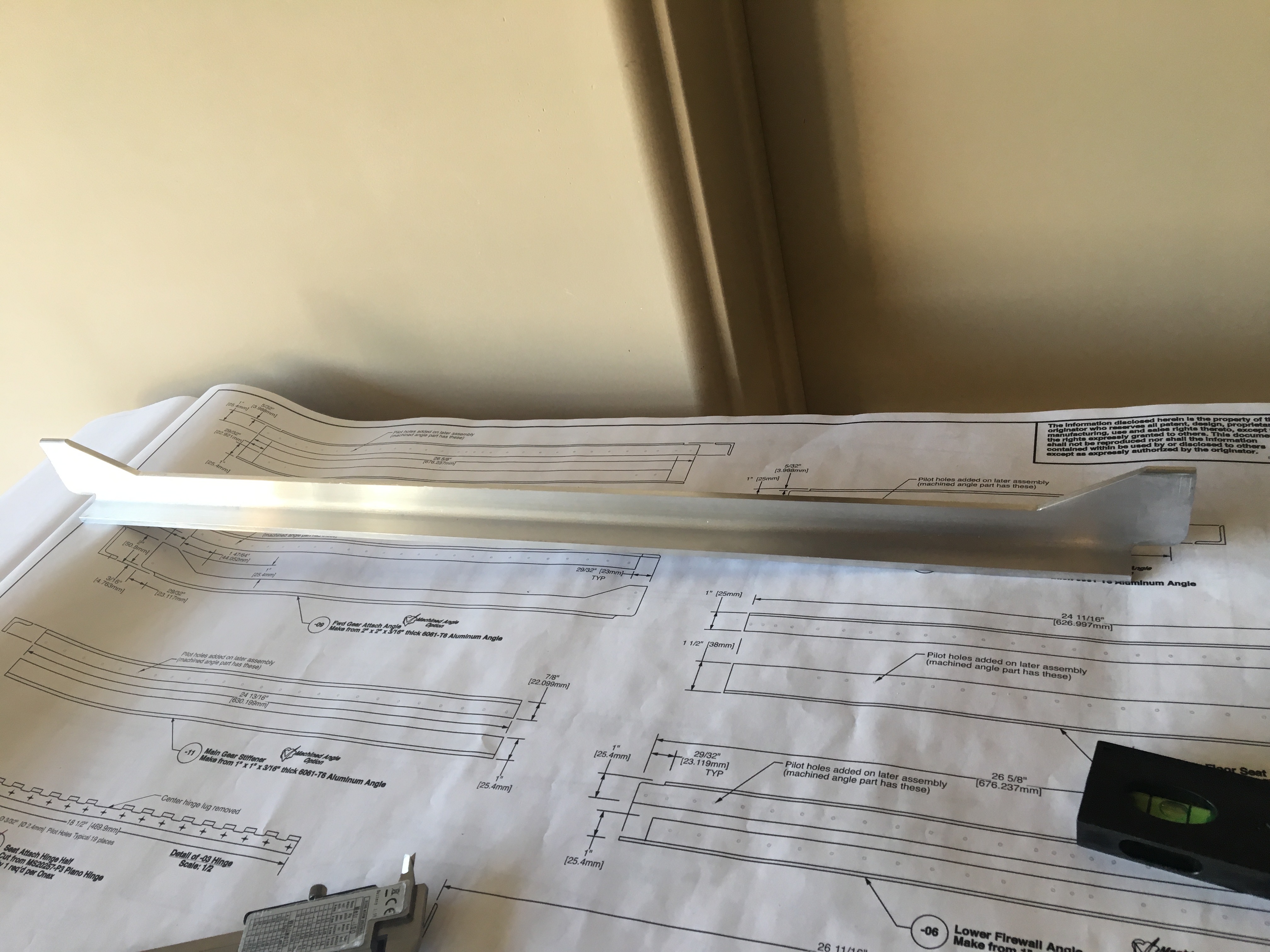

Then there’s the front gear brace, 3rd picture. This is cut from a hefty chunk of aluminum. It’s 2” x 2” extruded angle, 3/16th inches think. That’s more thank twice as thick as the typical angle parts required. It gave my band saw a workout. I spent a good amount of time filing it and polishing it to make it smooth and shiny. It too fit perfectly. Then I went back to the plans and noticed that three these gear braces are required. Back to the bandsaw to make two more…