Pickled Engine

Installed the secondary ignition stator. This involved a lot of removing, sanding, reinstalling, repeat. The stator (metal pickups that “stay” in place) is baked in a potting material to hold it all in place I presume. Unfortunately I should have taken a picture, but it’s on the inside of the center plate you see in the picture with the wires coming out. It fits in a cavity, just the right size, lines with strong magnets. So, putting the stator in place was a hazard to the fingers because the moment it gets within half an inch into position, POP!… the magnets pull it in severely pinching anything in the way. We were careful and managed to keep all our fingers. It’s a tight fit and there was a bit too much potting material. It took us several un-installations to adjust and make sure it fit without contact.

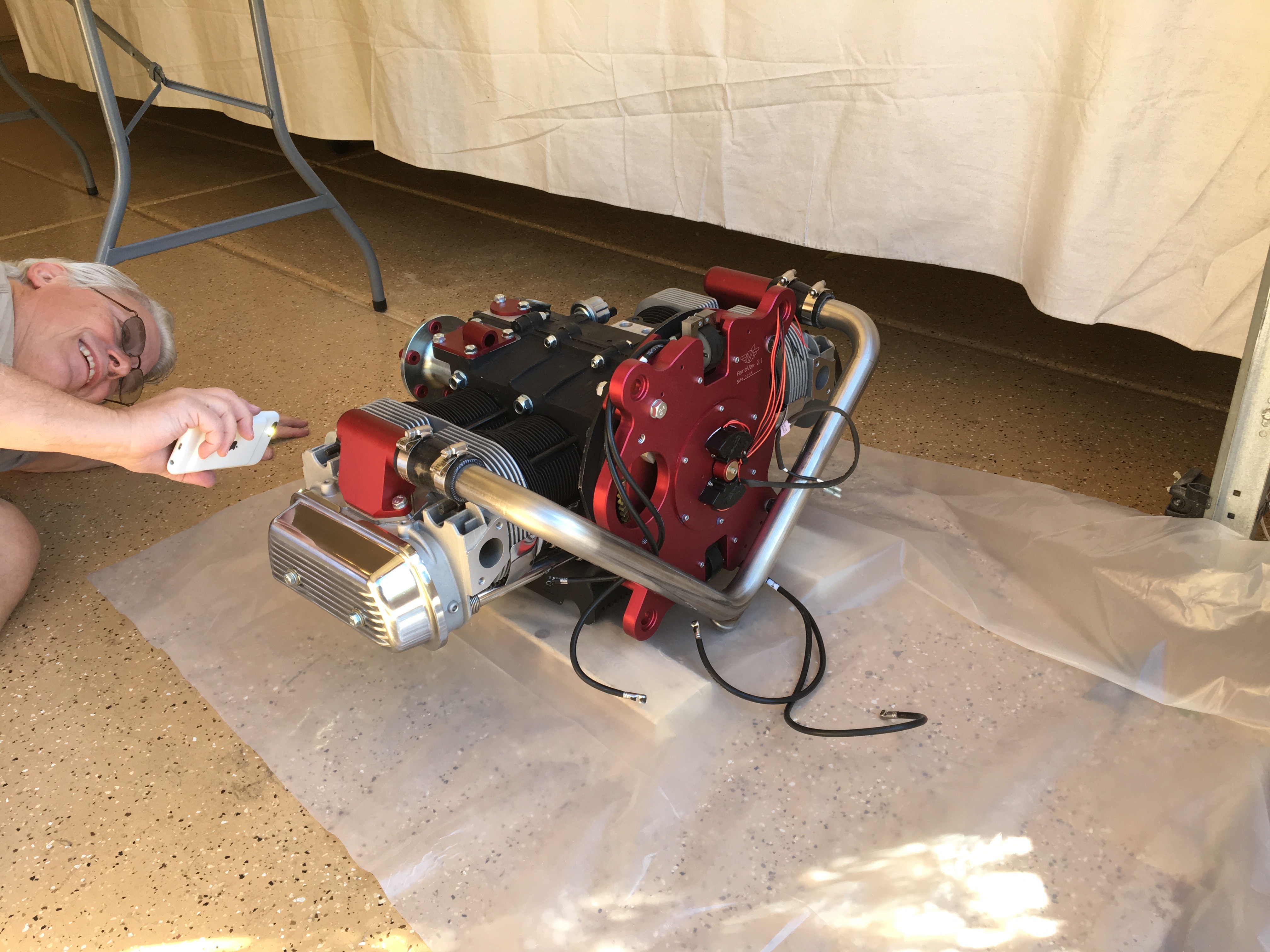

The engine is looking pretty tight now. It was time to pickle. We filled it with oil, no leaks! You can see dad on the ground searching for them. Then we plugged all the holes with paper towels and plastic, and covered the hole thing up with a sheet of plastic. One pickled engine, coming up.

Dad and I did some night practice, renewing our night currency. Again, wish I took some pictures because it was beautiful. -sigh-