Oh It's a Plane

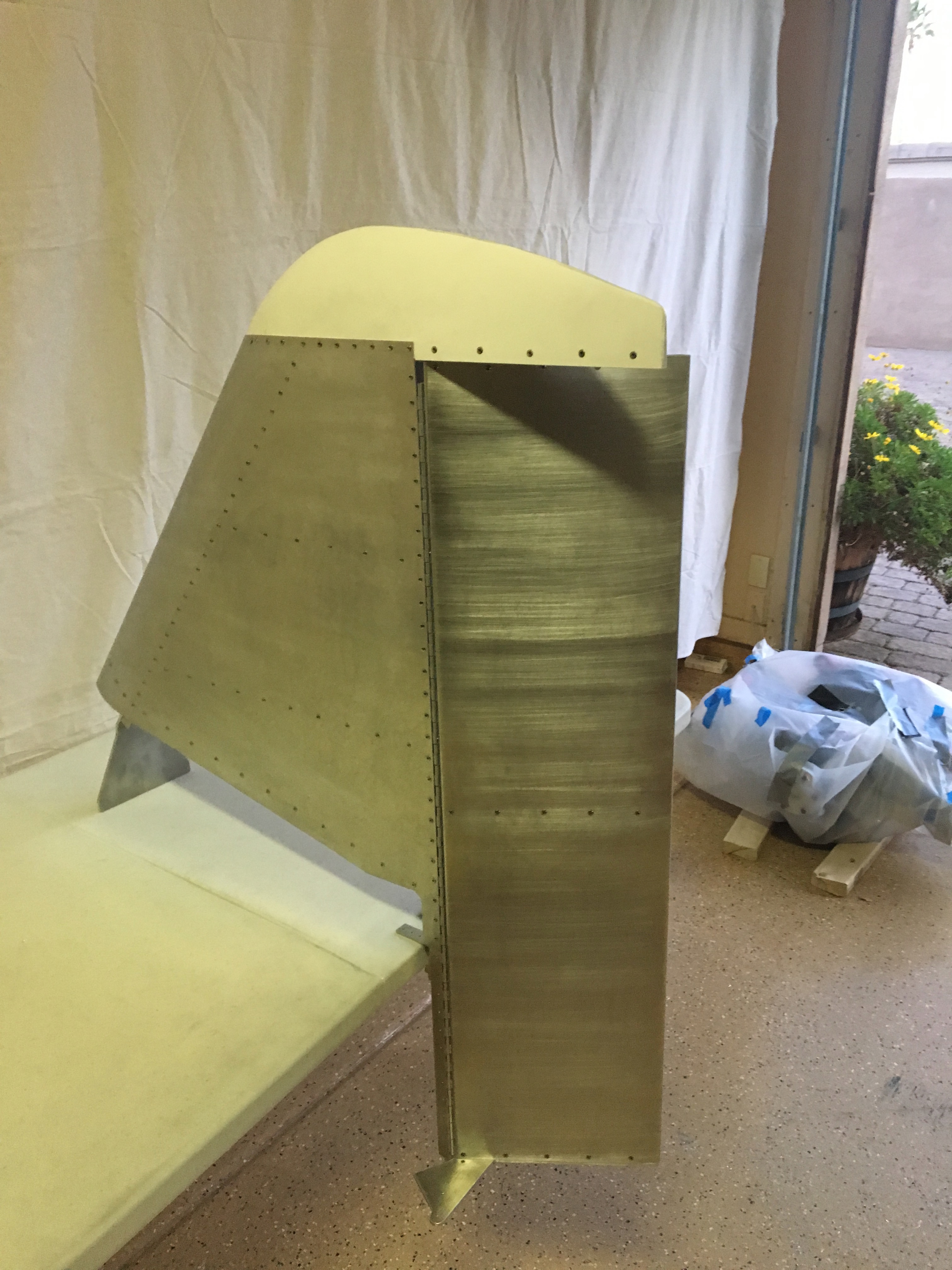

“Oh. It’s starting to look like an airplane.” That what people said when they walked into my shop today. And by the end of the day I finished the vertical tail. (whew) See the first pic.

Welding the spars and the ribs was uneventful. That vertical tail tip though… It took me a while to assemble all the parts with clecos sufficiently to seat the tip and figure out where to cut it. After plenty of tinkering I got it to fit just right, and ended up cutting about half an inch off. I figured out later that this had the adverse effect of shortening the length piece, front to back. When all assembled, the rudder now sticks out about a quarter inch past the tip. Aye! The first aesthetic defect! Perhaps no one will notice.

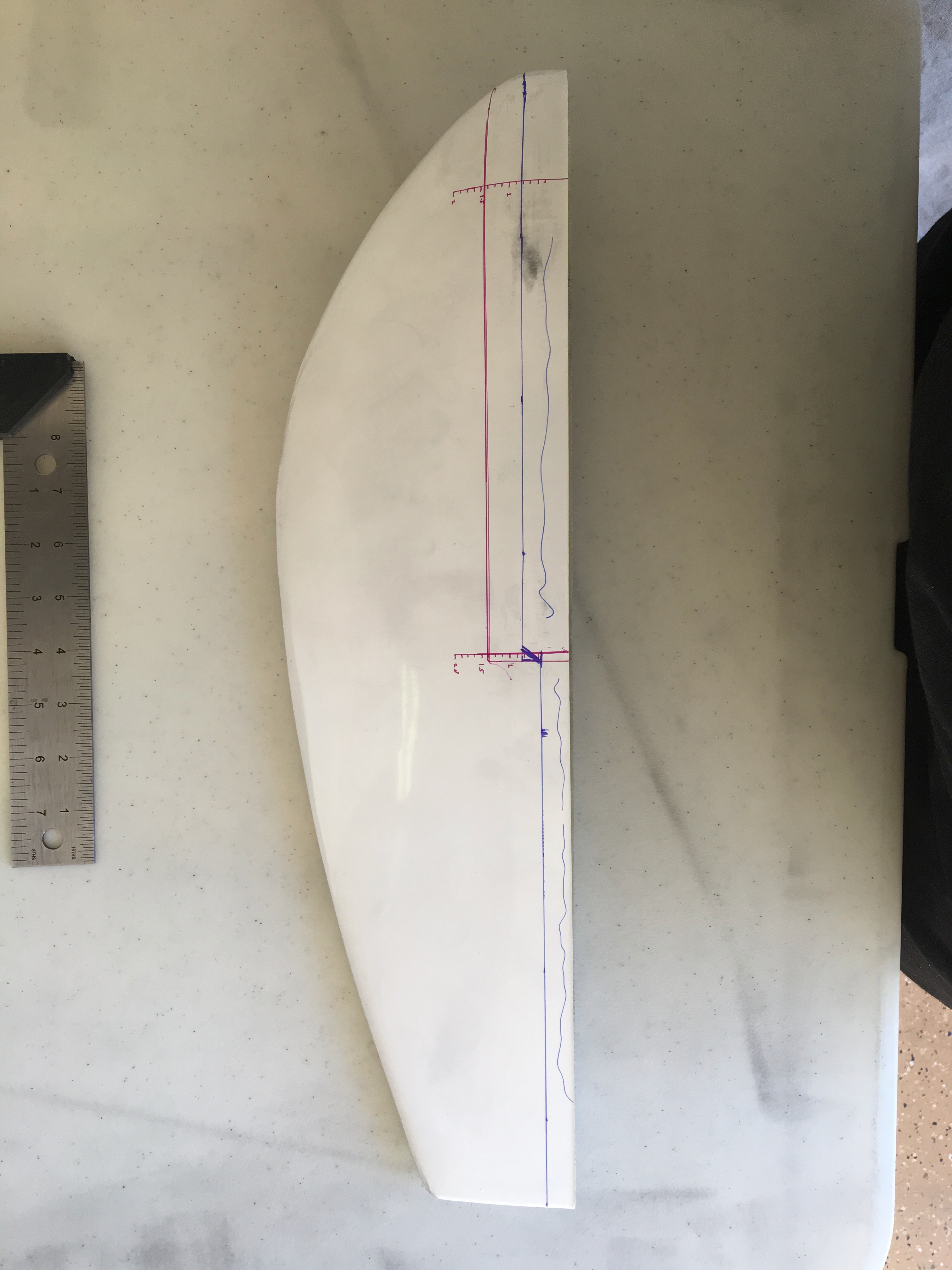

I’ve pondered this fiberglass tip for hours now and I know it intimately. My conclusion is that there’s no way to have both a streamlined leading edge and a flush trailing edge. You can have one or the other. The fiberglass tip that Sonex ships doesn’t fit their vertical tail. Maybe I’m wrong.

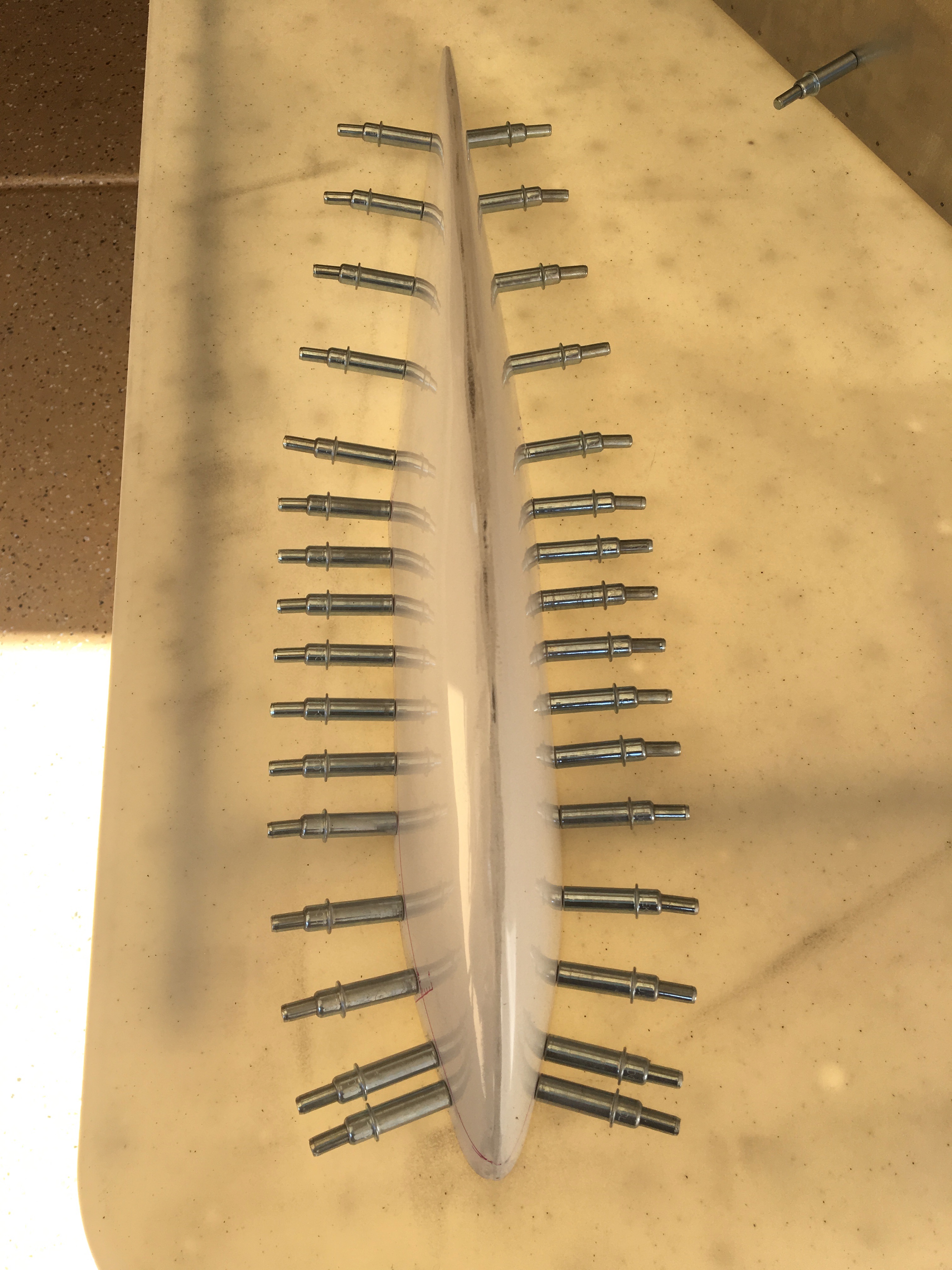

Anyhow, I drilled out the 32 holes in the fiberglass tip. It looked like a centipede with all the clecos sticking out. I thought it looked cool so I took a pic.

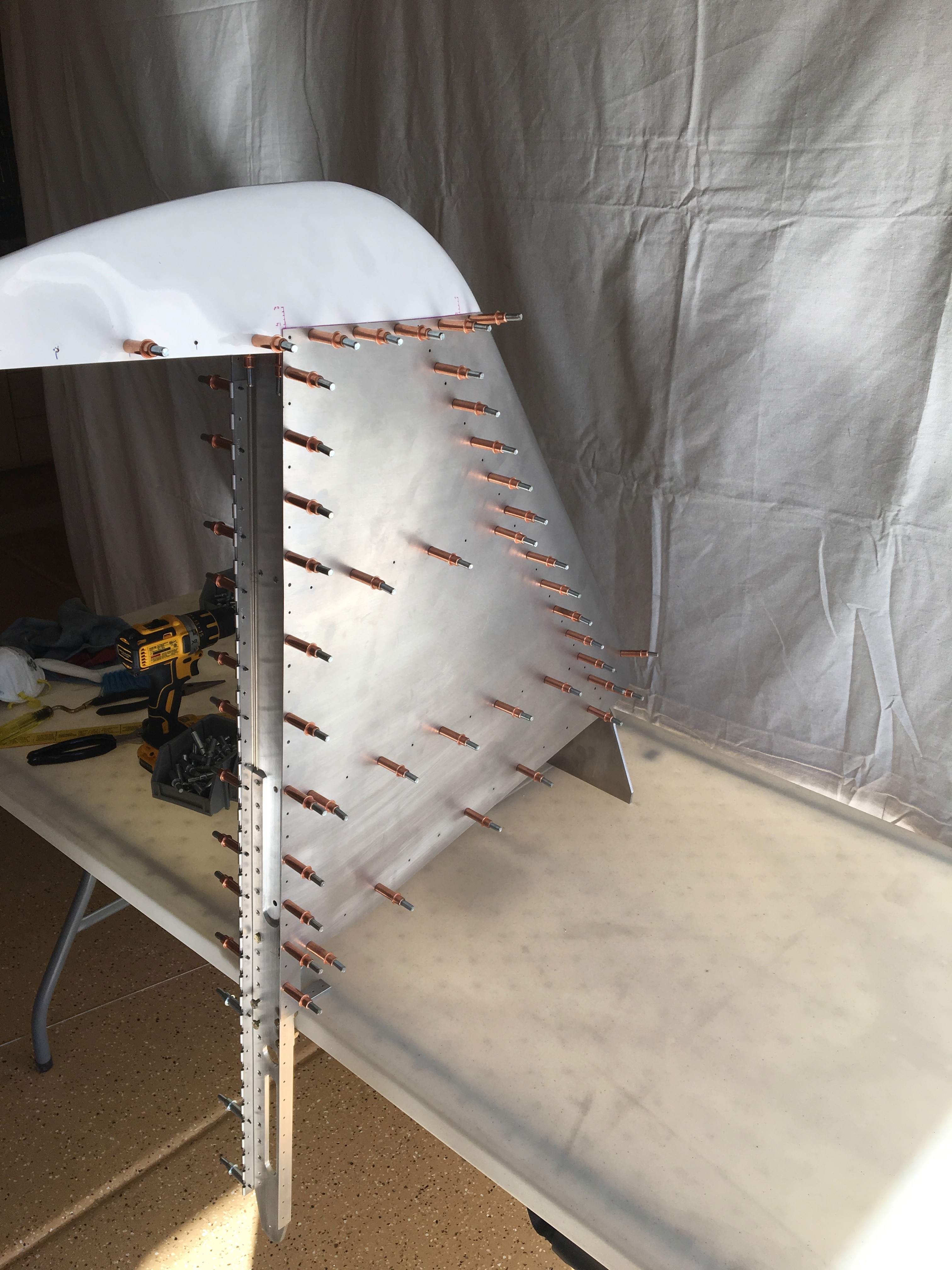

At this point I had assembled the vertical tail, with skin, about four times. A fifth assembly was required to begin the up-drilling. You can see all the silver clecos sticking out. After up-drilling, all the silver clecos had been replaced with copper clecos (they fit the bigger holes). Then the tail was disassembled, deburred, cleaned, and reassembled. After pulling about 200 rivets, done!

I’m pleased to have finished a recognizable airplane part. (patting self on back)