Got Hardware?

It’s been over a week! I had a nice visit with my aunt and uncle last week, and then my wife and I got started on taxes. But I’m back on the plane.

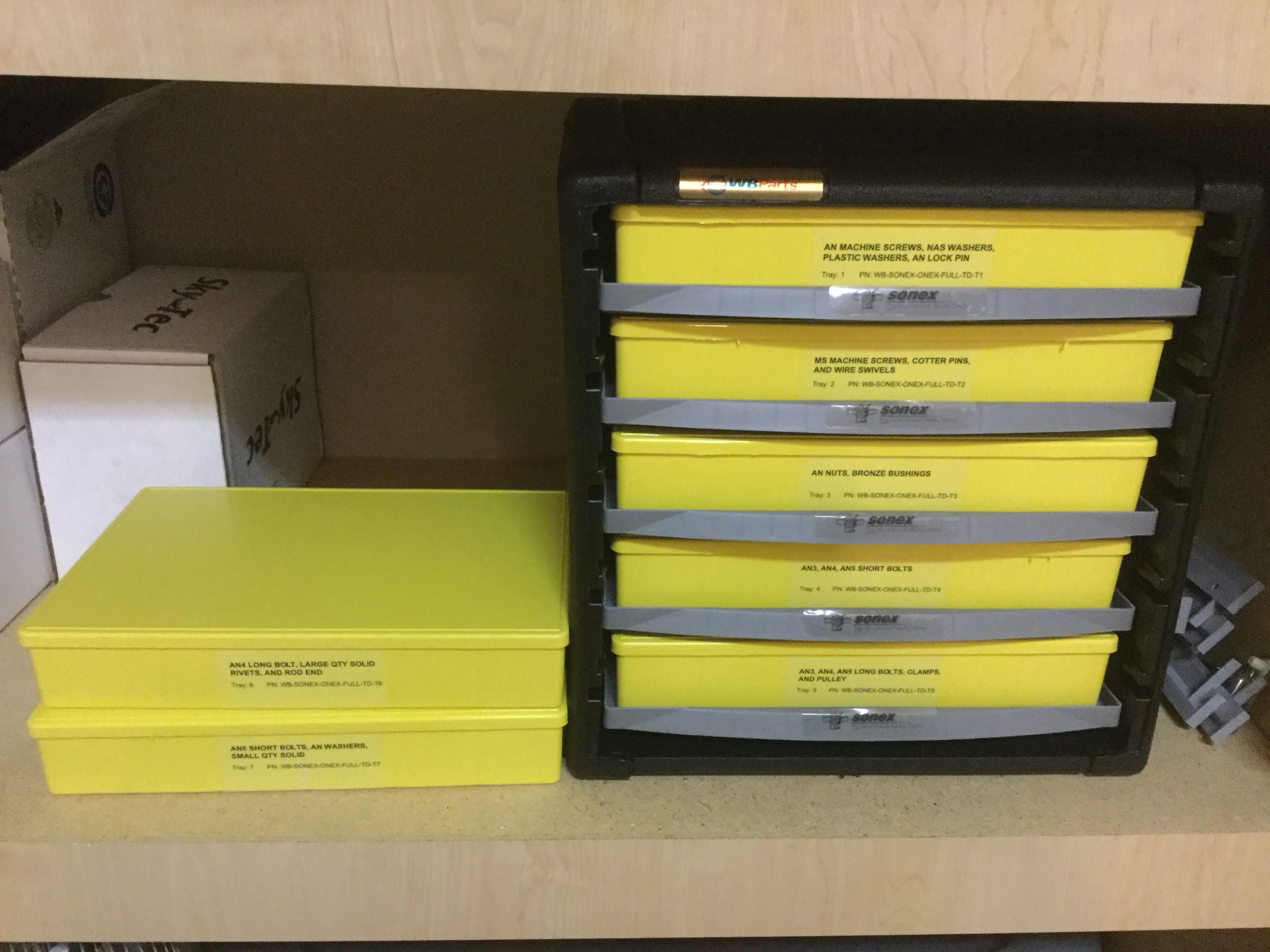

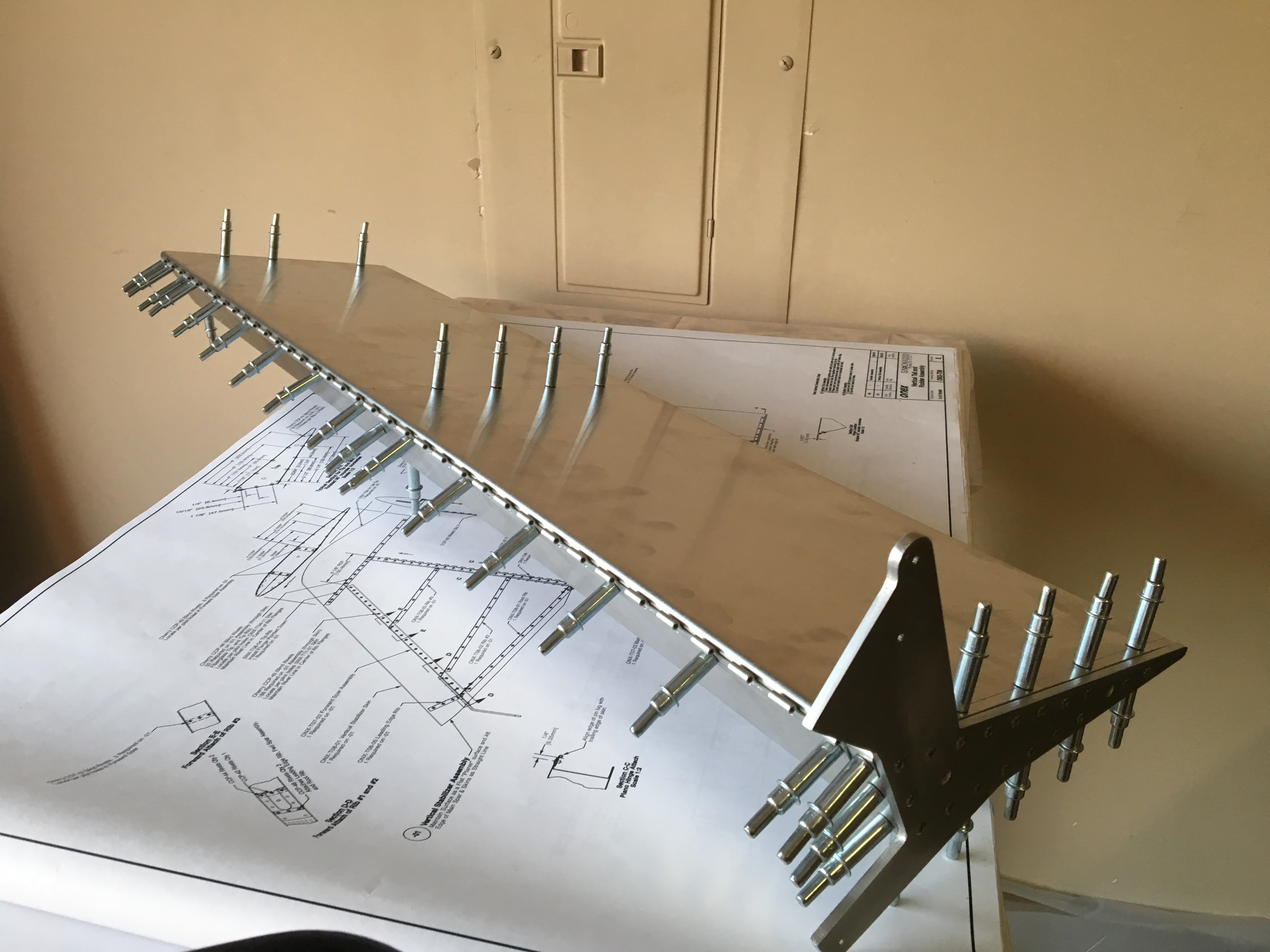

The hardware arrived yesterday. It came in these nice trays and a rack that you can see in the first pic. Classy! I inventories everything and it was all there except a pitot/static tube, so hopefully they’ll send that soon.

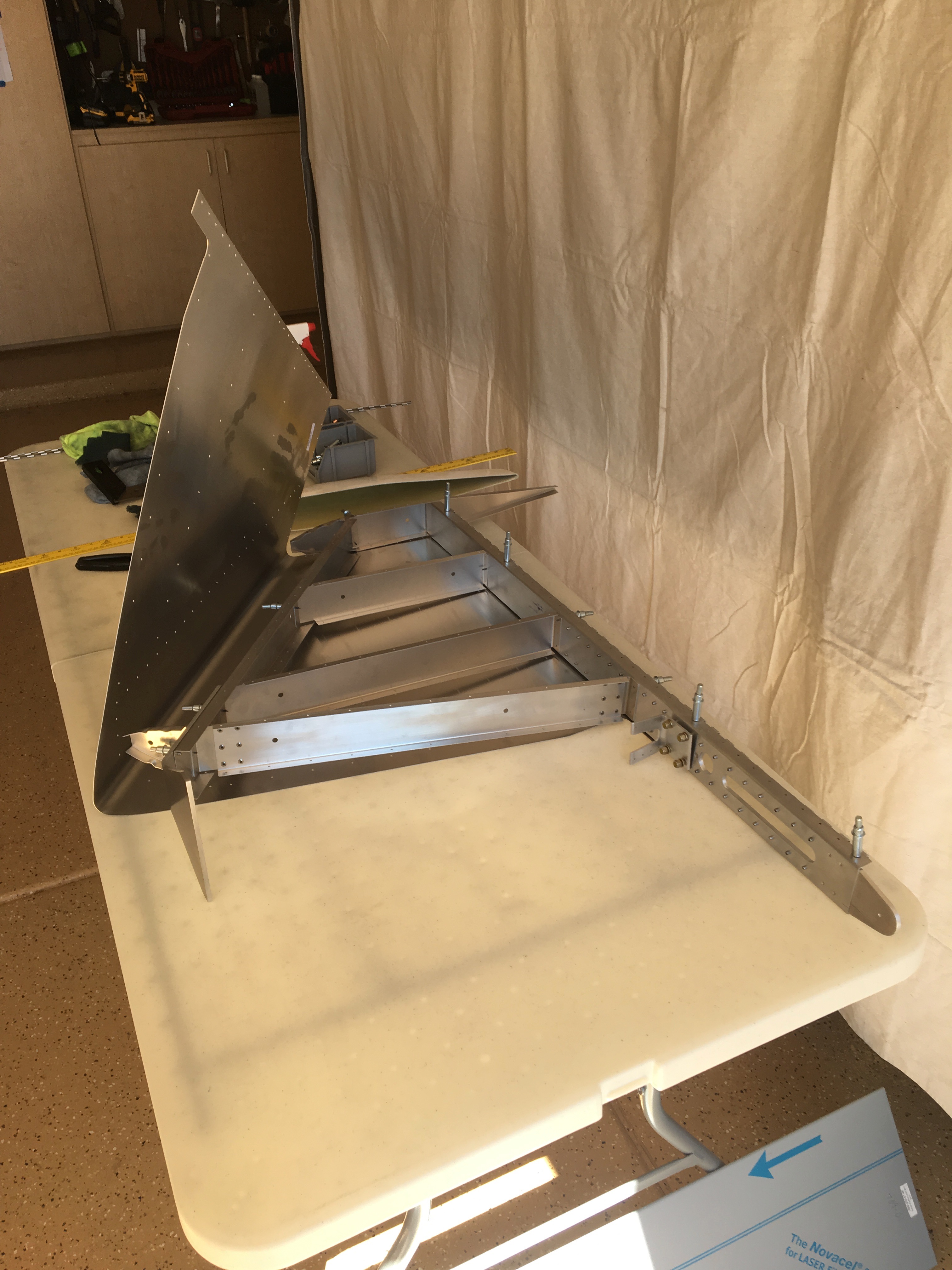

Having the hardware enable me to continue with the tail. I cut some piano hinge, and installed some bolts/washers/nuts. And with that I continued to assembling the vertical tail. This was is a big step. For the most part, everything fit together like a puzzle and all the holes line up. A second box of clecos was required to hole it all together. Before updrilling and riveting the parts, I want to make sure EVERYTHING plays nicely together and I’m doing it correctly.

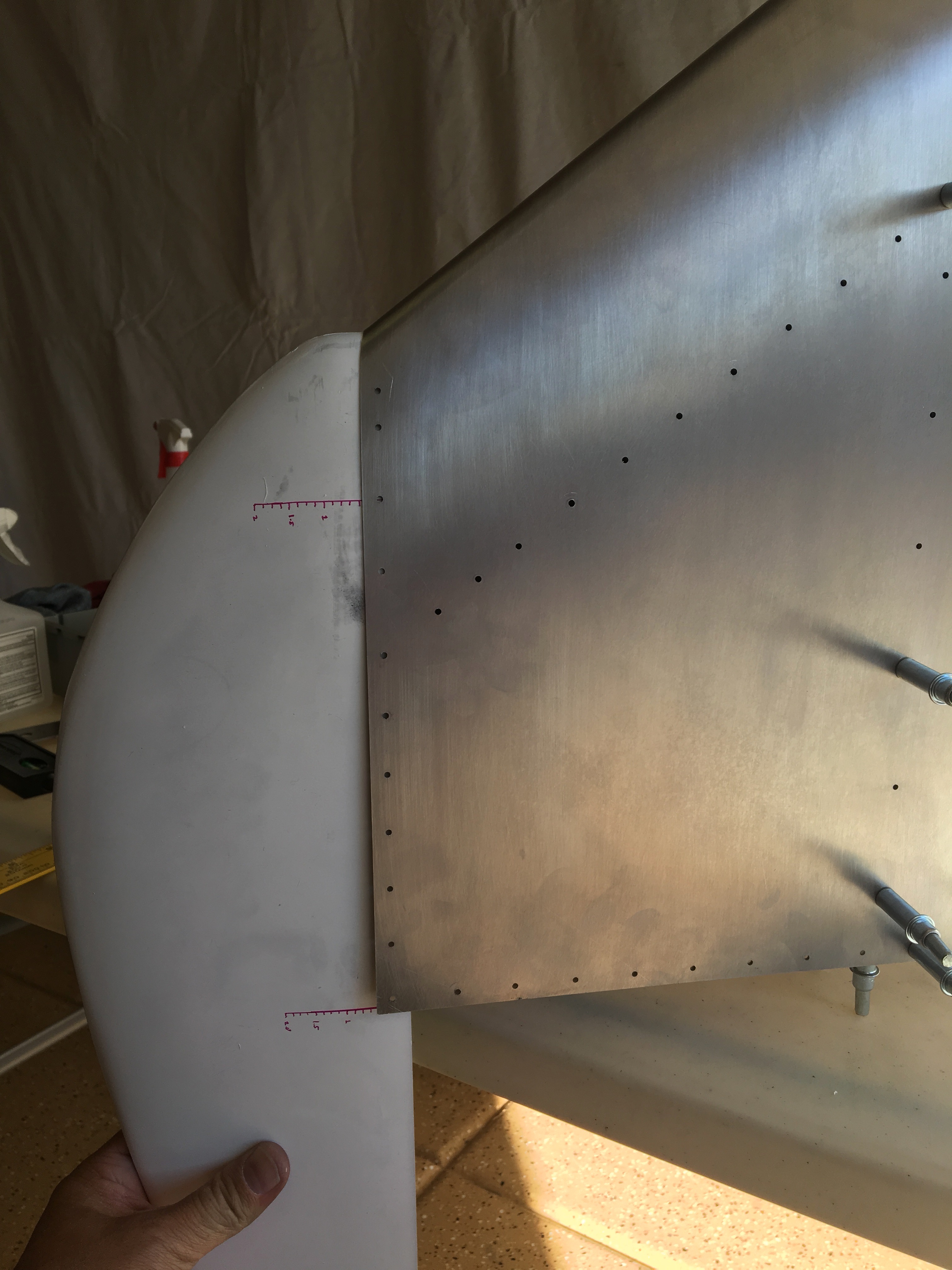

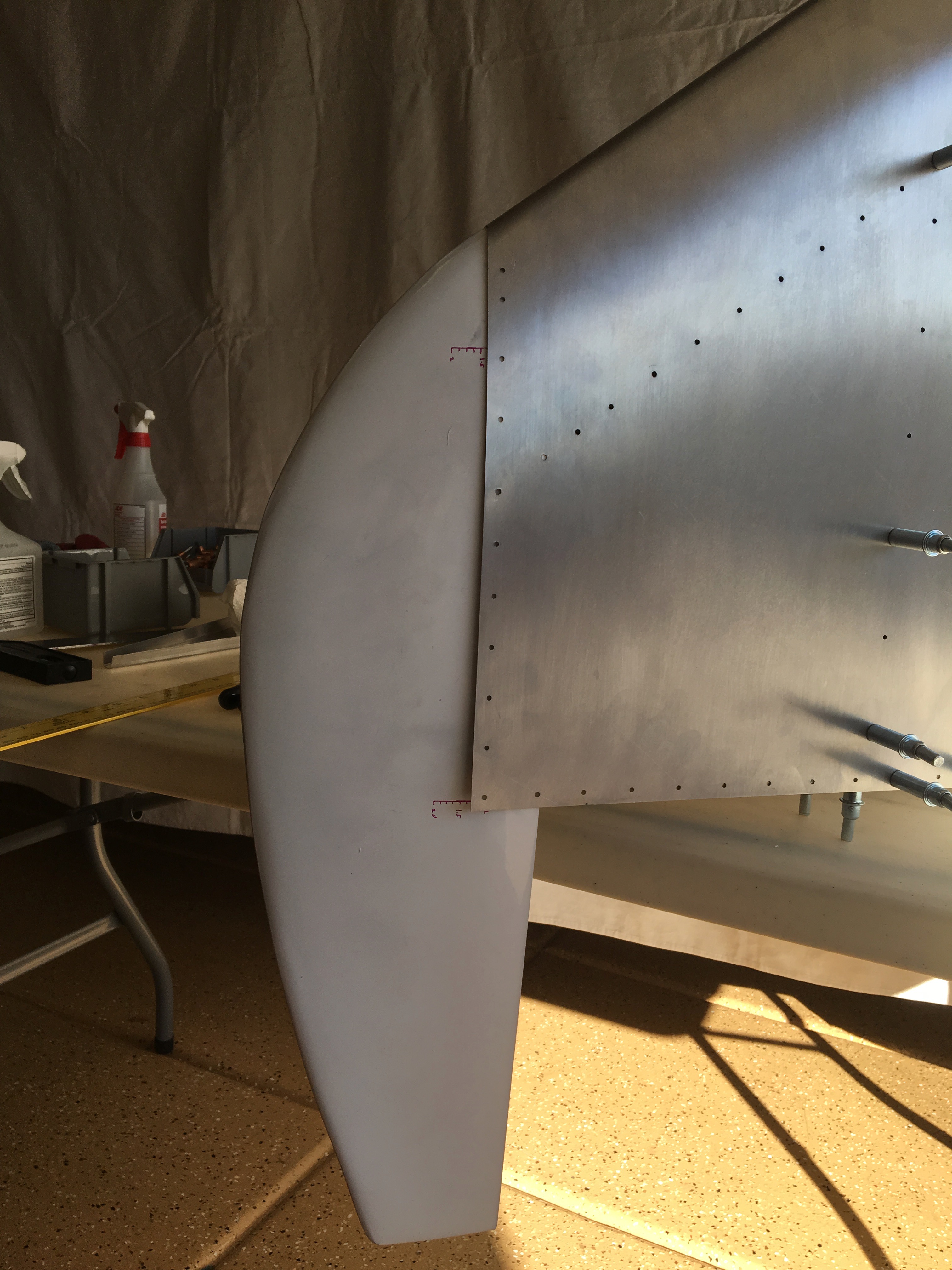

One problem I had was with the fiberglass tip. When slid into place, that is what seems to be the proper place, it sticks out like the hump of a beluga whale. See pic 3. That doesn’t look right. If I slide it in further, it looks better from a profile but it’s skinnier and the aluminum doesn’t fit as snug. I’m gonna have to call the pros on this one tomorrow.

That left the rudder which get’s attached to vertical tail. I had already prepared the skin and parts so this was a matter of measuring, more measuring, and then drilling and cleco-ing. I’m not sure there’s a reason not to rivet this so perhaps that’s what I’ll start with tomorrow. Although I wonder if I should dimple the skin so the rivets lie flush… Another question for tomorrow.