Breadth First Building

In the past week, I started on several tasks, unable to complete any for various reasons. However, much progress has been made.

Sonex Build Visits

Last Thursday I went to visit Denny and Jim at Deer Valley airport to check out their builds. It’s always fruitful to see how other people build their planes. I got plenty of ideas for improving my build. And I got a better sense of how to proceed with the engine and electronic components.

Jim’s hangar was my first stop. He’s been working on his Sonex for 12 years. Maybe that’s because there are lots of distractions at the airport. At least three people stopped by within an hour to chat and check out the build. Anyhow, Jim gave me a great tour and then got help from Denny to start up the engine and see how it ran. Purred like a tiger.

On the walk to Denny’s hangar I got a special treat. Hoa, another Sonex owner was cleaning his beautiful bird. He proudly presented his vinyl wrap job, which is truly nice. He outsourced it and paid less than half what a paint job costs. I still want to do my own wrap.

Denny’s Sonex has been flying for 9 years. He did a wonderful job building it and he’s put over 700 hours on it since.

In the afternoon after the visits, I did a bit of work on the wing fold. I wanted to better understand how they connect and fold. While looking at it, I notices some flat heads protruding where the outboard spar attaches. That’s not good. So I took it apart and cleaned it up.

On Friday, I pulled out AirWard’s fuel shutoff kit and began work. But I couldn’t figure it out so I emailed Dave. He helped me realize that there was a missing part that I was able to pick up at the hardware store.

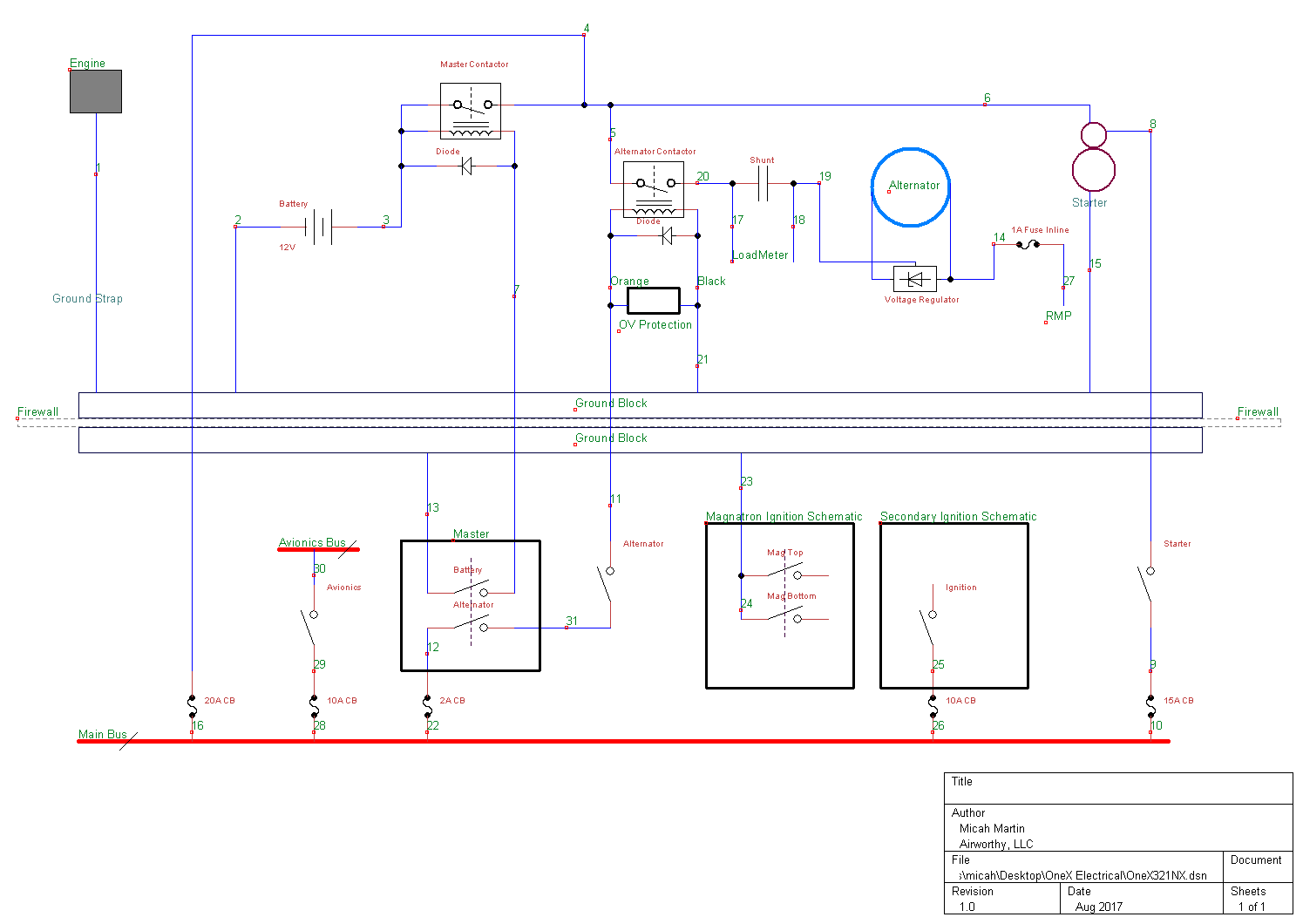

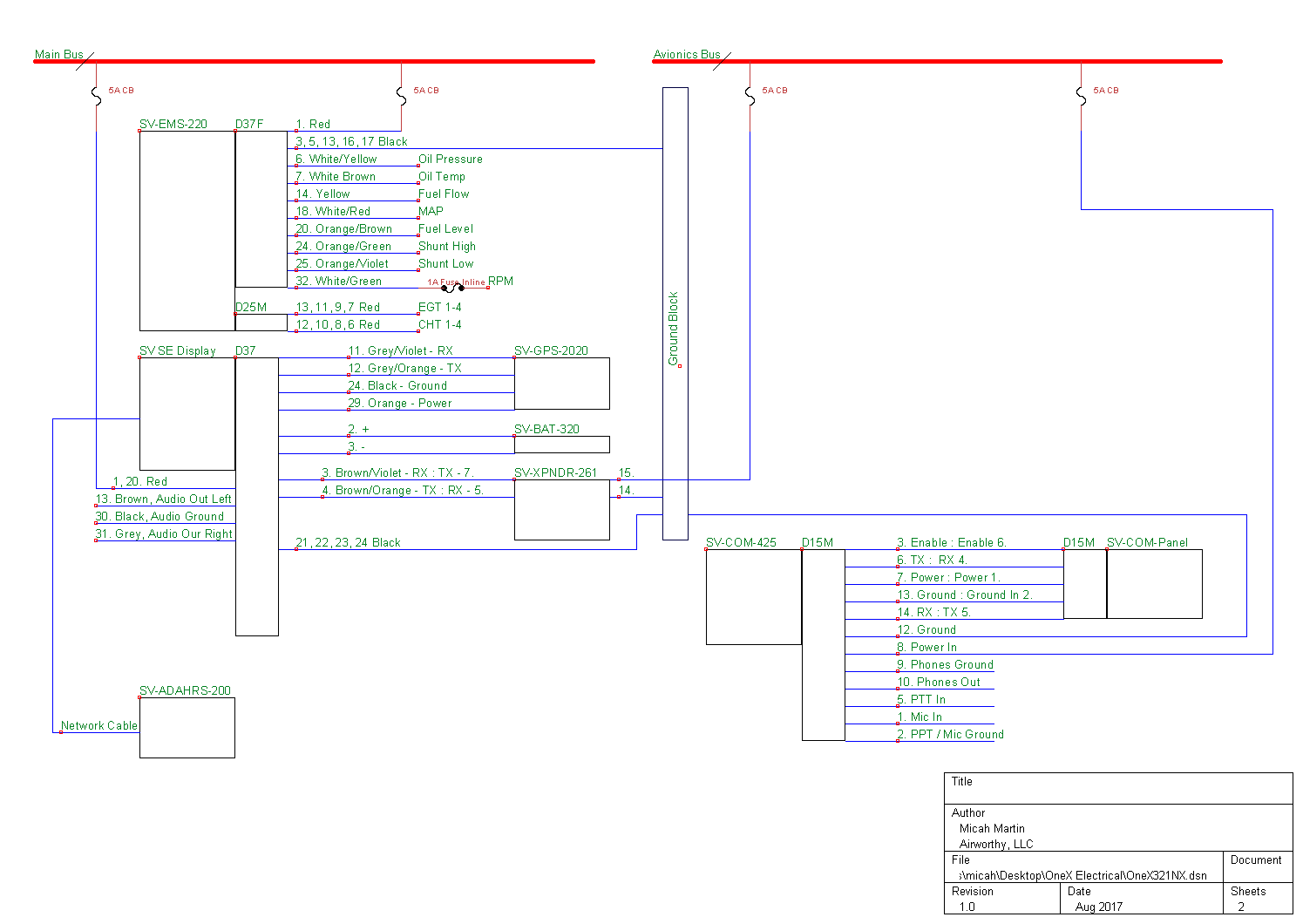

Electrical Diagrams

I received the Aircraft Wiring Guild over the week end and read it. Although short, it spelled out a lot of things that were not obvious to me. With what I learned, I was able to draw a couple schematics (below) of the electrical system I intend to build. This was intense! Very details oriented. What you can’t see is my spreadsheet detailing every wire; its gauge, ends points, terminators, and length. It took about 2 days.

With these, I was able to order all the wires, terminators, switches, and various electrical components I should need to wire everything together. I fear it may take quite a while to complete.

Fuel Shutoff

Another problem with the fuel shutoff kits is that Sonex has recently stoped building tanks with builtin ports and is including their Oops fittings instead. The Oops fitting is a threaded, flanged tube that has to be inserted from the inside of the tank. With a nut on the outside and rubber washers in and out, the Oops fitting seems very secure. But Dave, from AirWard, hadn’t updated his kit to accommodate the Oops fittings so I had to get a bit creative to make it work. But it does work, nicely.

There’s two more kits for the fuel system. The fuel system kit, which contains all the basic parts, and a kit to eliminate the infamous “Burp” symptom of the AeroInjector. The instructions for the burp kit were mind boggling. I emailed Dave some more. Eventually, after reading all the fuel system instructions multiple times and drawing diagrams, the system made sense and I could visualize it. Great! But the fuel components can’t interfere with the cowling, which hasn’t been installed yet.

Cowling

The fuel system is on hold so I can work on the cowling. Cutting and sanding fiberglass…. fun. It cuts like butter compared to metal, but fiberglass particles go everywhere (ichy), and the chemical smells can’t be healthy.

This project brings back painstaking memories of the windshield. The cowlings have to be cut in multiple places. Most annoying is the engine rocker covers that stick out the side on a OneX. The cowling won’t fit into place without the engine cover cut out. And you don’t know where to make the cutout without fitting the cowling into place. So it’s another game of install as much as possible, make tiny cuts, uninstall, cut, repeat.