Hundreds of Holes

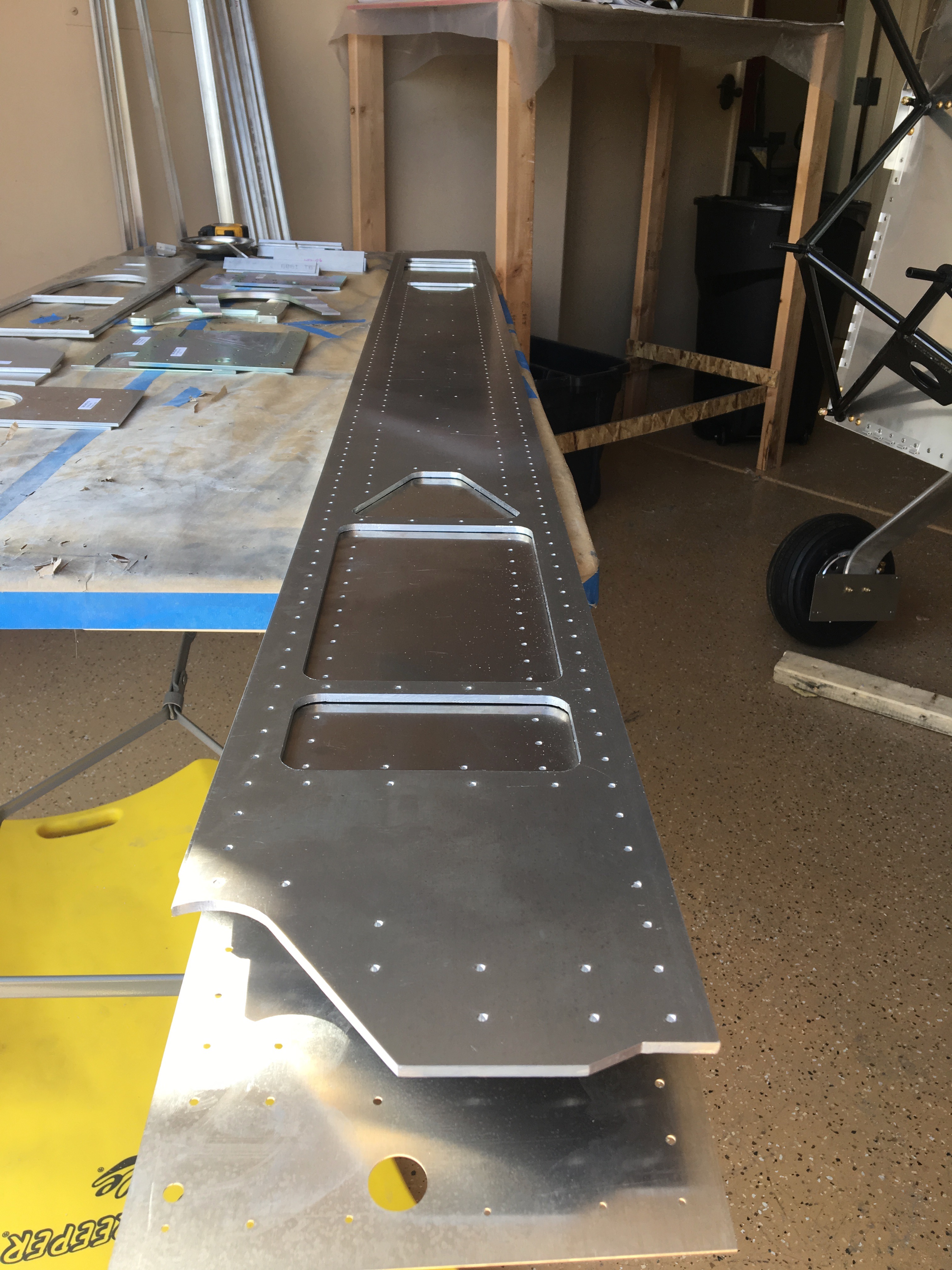

Friday was a busy day and I only got to work 4 hours fabricating parts for the main spar. This morning I fabricated about 8 more parts. Then the main spar webs. These are 2 long, heavy pieces of aluminum that provide the main structure of the main spar. They came prefabricated to the right shape with pilot holes, but the pilot holes are tiny, not even a pin hole. But thank goodness they are there. It would take a very long time to measure those 100’s of locations. And without a pilot hole, there’s always minor errors in where the drill actually penetrates the metal and they can add up. With the pilot hole, small though it may be, the drill bit tends to seek it out and follow it through making precisely located holes.

It took hours to drill all those holes. Note there are two layers in the picture, the bottom layer as more holes than the top. I got a work out wrestling those parts to hold still in the right place on the drill press, 100’s of times. Then it took hours to debur. I also filed the edges to remove stress risers. Tedious work. Now they are ready to mate with the the other spar parts and I’ll get to up-drill all the holes and debur them again!